Sustainability-Initiatives for SDGs-

As a manufacturer of forged flanges and other forged products for piping, Shimoda Flange has been earning the trust of customers due to a wide range of material stocks and cultivated technologies for forging, heat treatment and machining over many years. Simultaneously, we have always been proactive in developing new technologies.

In particular, since the end of the 20th century, there has been a call for a reduction of greenhouse gases. In order to meet these demands, new thermal power generation systems using even higher pressures and temperatures on supercritical water has been developed in order to improve efficiency. Since these new plants demand high strength and high corrosion-resistant piping components, Shimoda Flange has met these demands and has contributed to the practical application of these high-grade piping components.

However, it is well known that the demands of the era are undergoing a phase change from "Low-carbonization to Decarbonization" due to the recent remarkable global warming and the frequent occurrence of natural disasters. As a consequence, we are now focusing our efforts on expanding our contribution to the field of "Decarbonization" in areas such as wind power generation and geothermal power generation. We are doing this in parallel with the continued improvement and development of the conventional technologies for "Low-carbonization".

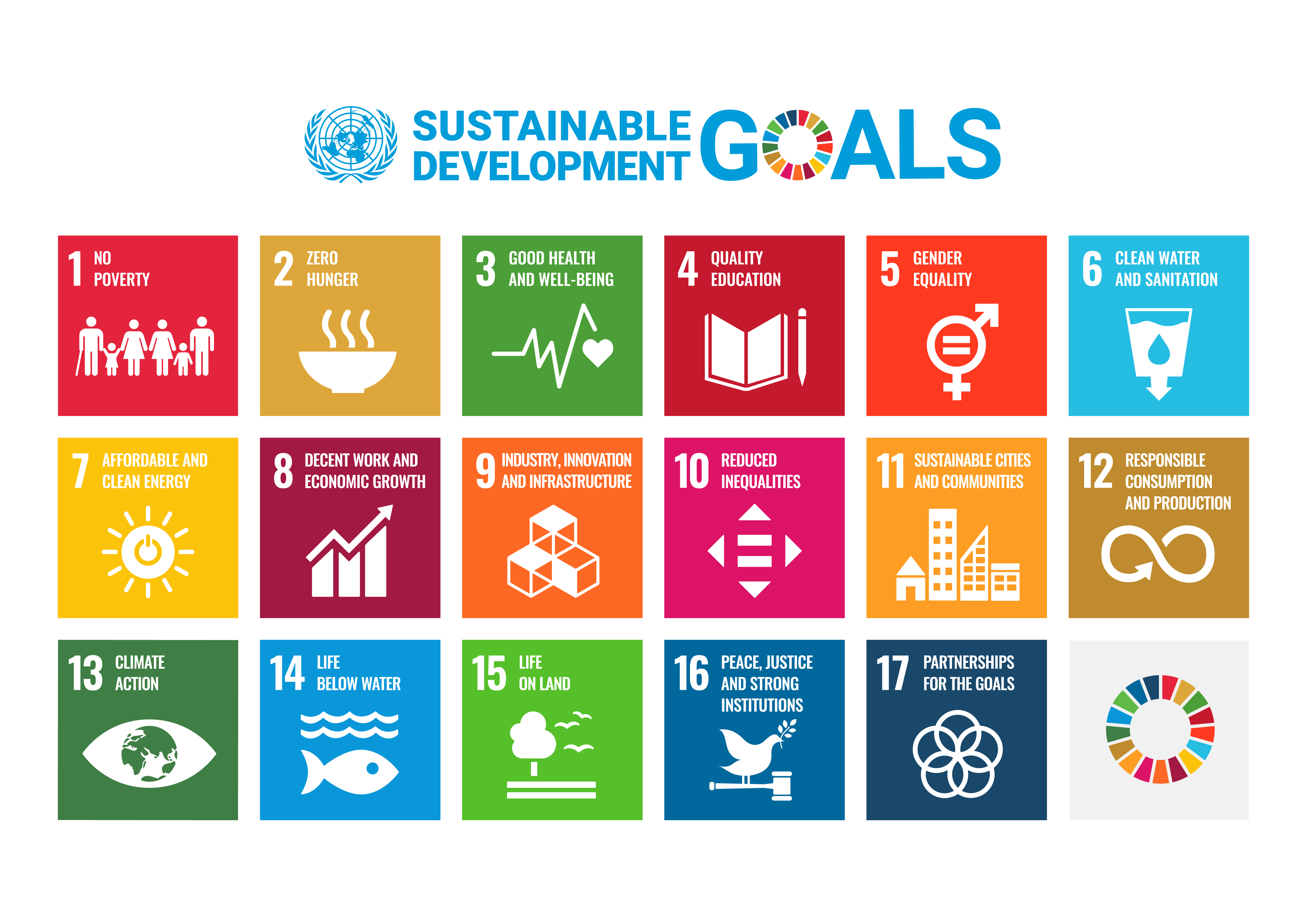

Among the 17 goals of the Sustainable Development Goals (SDGs) adopted by the United Nations in 2015, two goals stand out for us here at Shimoda Flange. One of which is to realize a decarbonized society depending on clean energy (7th goal). The other is to create "The Circular Economy" which prevents the depletion of limited natural resources (12th goal). Both of these goals gives us important stimulus and focus in conducting our future activities. As a company we plan to make our best contribution in order to achieve these goals by utilizing cultivated manufacturing technologies.

Of course alongside the more global aspects of meeting the listed SDGs Shimoda Flange also makes every effort to educate and develop our employees on the benefits and improvements that can be made directly within the company.

In particular, since the end of the 20th century, there has been a call for a reduction of greenhouse gases. In order to meet these demands, new thermal power generation systems using even higher pressures and temperatures on supercritical water has been developed in order to improve efficiency. Since these new plants demand high strength and high corrosion-resistant piping components, Shimoda Flange has met these demands and has contributed to the practical application of these high-grade piping components.

However, it is well known that the demands of the era are undergoing a phase change from "Low-carbonization to Decarbonization" due to the recent remarkable global warming and the frequent occurrence of natural disasters. As a consequence, we are now focusing our efforts on expanding our contribution to the field of "Decarbonization" in areas such as wind power generation and geothermal power generation. We are doing this in parallel with the continued improvement and development of the conventional technologies for "Low-carbonization".

Among the 17 goals of the Sustainable Development Goals (SDGs) adopted by the United Nations in 2015, two goals stand out for us here at Shimoda Flange. One of which is to realize a decarbonized society depending on clean energy (7th goal). The other is to create "The Circular Economy" which prevents the depletion of limited natural resources (12th goal). Both of these goals gives us important stimulus and focus in conducting our future activities. As a company we plan to make our best contribution in order to achieve these goals by utilizing cultivated manufacturing technologies.

Of course alongside the more global aspects of meeting the listed SDGs Shimoda Flange also makes every effort to educate and develop our employees on the benefits and improvements that can be made directly within the company.

Shimoda's initiatives

Global Environmental Sustainabilty

- Eliminating the causes of environmental damage -

| Theme | Action | SDGs |

|---|---|---|

| Toward carbon neutral - Contribution through our products - | Delivery of products for LNG thermal power generation (GTCC) |

|

| #rowspan# | Delivery of products for clean coal technologies (A-USC, IGCC) |

|

| #rowspan# | Delivery of products for renewable energy power plants such as wind power, geothermal power and biomass power. |

|

| #rowspan# | Delivery of products for SAF(Sustainable Airline Fuel) plant. |

|

| #rowspan# | Delivery of products for liquefied hydrogen carrier. |

|

| #rowspan# | Delivery of products for ammonia carrier and liquefied CO2 carrier. |

|

| #rowspan# | Delivery of products for ITER (International Thermonuclear Experimental Reactor). |

|

| #rowspan# | Establishing a supply chain with Euskalforging for large diameter flanges for offshore wind turbines. |

|

| Reduce CO2 emissions from our plants | Installation of solar panels on our plant. |

|

| #rowspan# | Reduce fuel consumption thanks to modernizing heat treatment furnaces. |

|

| #rowspan# | Introduction of EV forklifts. |

|

| #rowspan# | Introduction of energy-saving equipment such as LED lighting, inverter motors, etc. |

|

| #rowspan# | Periodical monitoring of CO2 emissions, including affiliated companies. |

|

| Environmental protection | Operation of ISO14001 environmental management system. |

|

| #rowspan# | Promote inhouse greening and evaluate its CO2 absorption effect. |

|

Resource Sustainabilty

- Saving and reusing limited resources -

| Theme | Action | SDGs |

|---|---|---|

| Contribution to a recycling society | Promoting Reduce, Reuse and Recycling. |

|

| #rowspan# | Development of Near Net Shape manufacturing technology (HIP, polygonal drawing, 3D printing). |

|

| #rowspan# | Direct scrap return of high alloy materials. |

|

| #rowspan# | Installation of rainwater storage tanks. |

|

| #rowspan# | Application of recycled products such as recycled umbrellas. |

|

Bio Sustainabilty

- Maintaining plant and animal diversity -

| Theme | Action | SDGs |

|---|---|---|

| Maintaining biodiversity of land and sea | Participating in a project to utilize forest thinning materials. |

|

| #rowspan# | Participating in a project to maintain rice terraces. |

|

Land and Infrastructure Sustainabilty

- National resilience (Disaster prevention) -

| Theme | Action | SDGs |

|---|---|---|

| National resilience | Development of steel pile joints for landslide prevention. |

|

| #rowspan# | Disaster prevention lecture and volunteer activities by an employee qualified as a disaster prevention specialist. |

|

Safety and Health Sustainabilty

- Guarantee of a peaceful and happy day life -

| Theme | Action | SDGs |

|---|---|---|

| Employee safety and health | Promoting health and safety initiatives. |

|

| #rowspan# | Certified as a "Health and Productivity Management Excellent Corporation" by METI. |

|

| #rowspan# | Complete no-smoking at work. |

|

| #rowspan# | Introducing "Vegetables at the office": Healthy lunch and reducing food waste. |

|

| #rowspan# | Introduction of "Three Major Illness Insurance". |

|

| #rowspan# | Prevention against heatstroke (distributing beverages, providing cooling vests, etc.) |

|

| Community life support | Supporting community cafeterias for children. |

|

Diversity

- Respect for human rights and equal opportunities -

| Theme | Action | SDGs |

|---|---|---|

| Diversity | Promoting female employment. |

|

| #rowspan# | Maternity and childcare leave system. |

|

| #rowspan# | Maintaining a good working environment for women. |

|

| #rowspan# | Inviting a social insurance and labor consultant as a director. |

|

| #rowspan# | Organizing the Harassment Prevention Committee. |

|

| #rowspan# | Participation in the Human Rights Education Promotion Council of Aioi city. |

|

Business Sustainability

- Business Continuity Strategy -

| Theme | Action | SDGs |

|---|---|---|

| Business sustainability strategy | Business Continuity Plan (BCP) certified by METI. |

|

| New technologies and new markets | Development of mechanical joints for civil engineering. |

|

| #rowspan# | Development and patent acquisition of new multi-start thread processing technology. |

|

| #rowspan# | Development of manufacturing technology for large complex shaped products by powder HIP process. |

|

| #rowspan# | Expanding sales channels to the aviation, space and defense industries by acquiring JIS Q9100 certification. |

|

| #rowspan# | Development of drawing technology for high alloyed polygonal bar by a new drawing line. |

|

| #rowspan# | Development of new products by WAAM metal 3D printers. |

|

| #rowspan# | "Susterial" (Sustainable + Material) has been registered as our trademark. |

|

| Good office Good communication | Sustainable office layout. |

|

| #rowspan# | Satellite office at the workshop. |

|

| #rowspan# | Half alternative three-day holidays in summer. |

|

| #rowspan# | Promoting inhouse sports events. |

|

| Human resources | Employment extension for senior skilled workers. |

|

| #rowspan# | Promoting official personal qualifications with financial support. |

|

| #rowspan# | Scholarship repayment support system. |

|

| #rowspan# | Welcoming interns from high school students. |

|

| Digitalization | Digital caliper with automatic data import system. |

|

| #rowspan# | Automatic inventory management and ordering system for cutting tools. |

|

| Corporate compliance | Adherence to compliance guidelines. |

|

| Information security | Organization of the Information Management Committee. |

|

| #rowspan# | Logging and analysis by SKYSEA system. |

|

| #rowspan# | Network guard system (FortiGate). |

|

Community Sustainability

- Partnership -

| Theme | Action | SDGs |

|---|---|---|

| Joint development | Joint research and development with other companies. |

|

| #rowspan# | "Go-Tech" joint development adopted by METI. |

|

| Harmony with the local community | Supporting local community events. |

|

| #rowspan# | Supporting SDGs events hosted by an university. |

|

| #rowspan# | Visiting and teaching at a local high school. |

|

| #rowspan# | A member of Hyogo Metal Belt Consortium. |

|

日本語

日本語