The 3D Metal Printer will be installed in our plant in this summer.

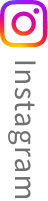

This summer, we will install the 3D metal printing system named “MX3D M1 System” assembled by MX3D (Amsterdam, Netherlands). It is the first installation of this system in Japan.

The M1 system is MX3D’s turnkey solution to print with robotic WAAM (Wire Arc Additive Manufacturing) procedure which is a large scale 3D metal printing process based on the layer by layer built up of welding. This fully-equipped WAAM system is composed of an off-the-shelf welding robot, MIG/MAG welding device and MetalXL control system developed by MX3D.

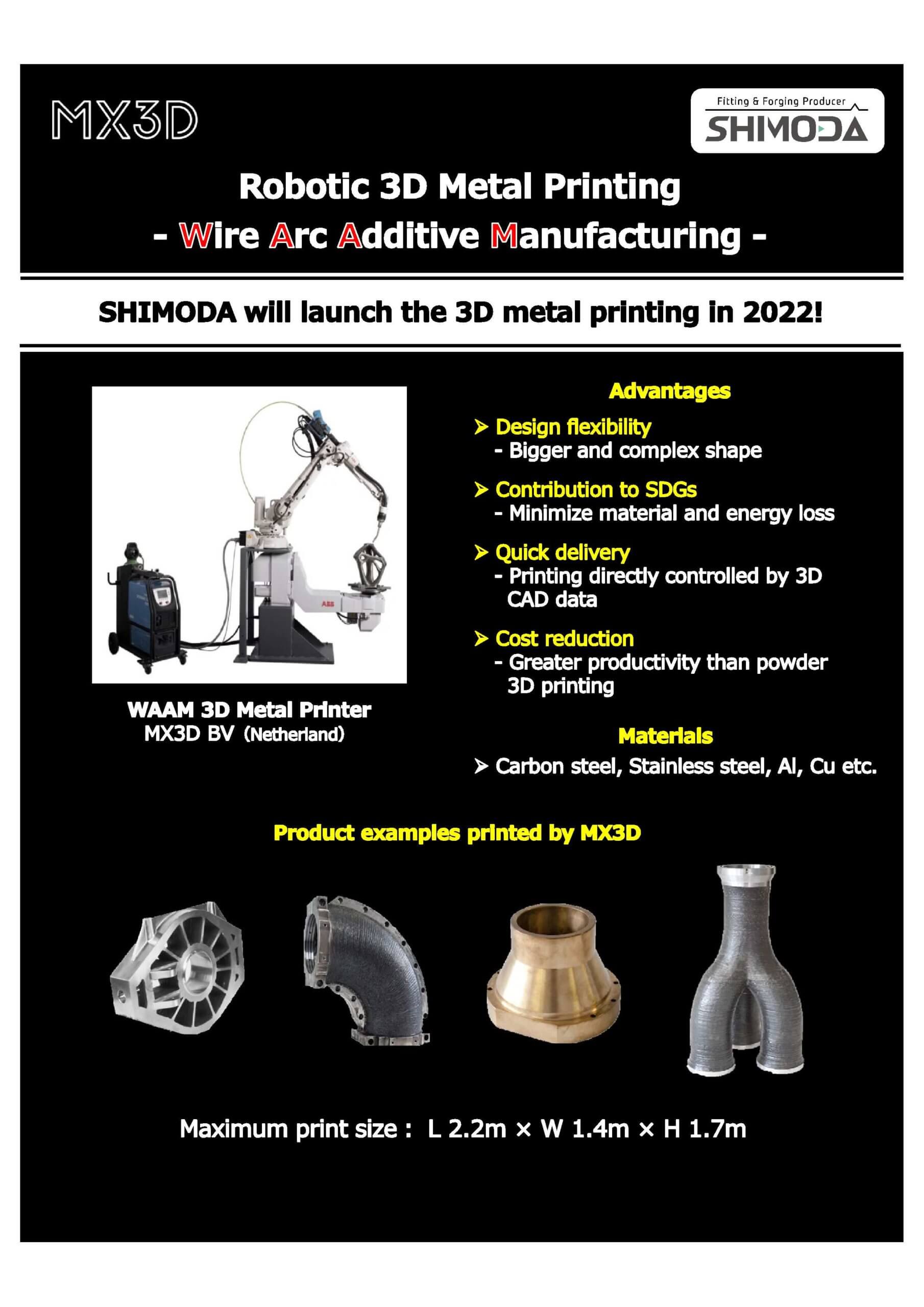

Our traditional products, forged steel flanges and fittings, are manufactured by forging and NC machining, however this 3D metal printer can make it possible to manufacture large products having more complex shape. Therefore we are expecting to apply this process to new products for new markets. In addition, this process is able to minimize the material and energy loss thanks to its Near Net Shape printing. We believe it will make a significant contribution to the SDGs that we are currently focusing on.

The maximum size of the product is 2.2m wide x 1.4m long x 1.7m high.

We are longing for your contact to apply this new process to your products.

日本語

日本語