company

Corporate history

Following our founding in 1946, we started to manufacture standard series of steel flanges in 1963. However,in 1984, we changed our strategy to focus our business on high-end products. Since then, we have delivered various special forged components manufactured by our experienced and unique technologies not only to domestic markets but also to all over the world. Recently we have been challenging new products by means of utilizing our cultivated technologies.

1946

Foundation

Shinichi SHIMODA founded a marine part manufacturing factory at Matsumae-cho, Aioi city as a subcontractor of Harima Shipyard.

1948

Establishment

Shimoda Tekkosho Co., Ltd. was established at Asahi-cho, Aioi city.

1963

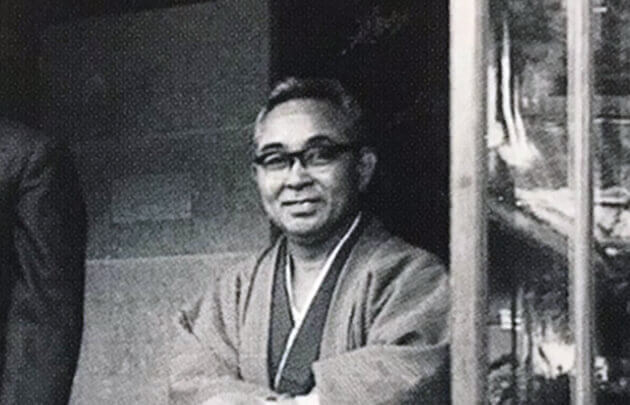

To a flange producer

Office and the main plant were relocated to Ryusen-cho, Aioi city (present location). Started as a specialized steel flange manufacturer.

1965

Excellent entrepreneurial recognition

Awarded a prize as an excellent entrepreneur by the Director of the Small & Medium Enterprise Agency.

1975

New Tatsuno Plant

Tatsuno Plant is newly constructed at Kitayama, Tatsuno city.

1976

From ocean to land

Changed our main business from the ship building industry to land based industries.

1980

Development of high grade products

Obtained a large volume order of high grade flanges for an Alaska pipe line.

1984

To a high-end fitting and forging producer

Withdrew from the plate flange markets. Our new strategy refocused on to the high-end forged products.

1987

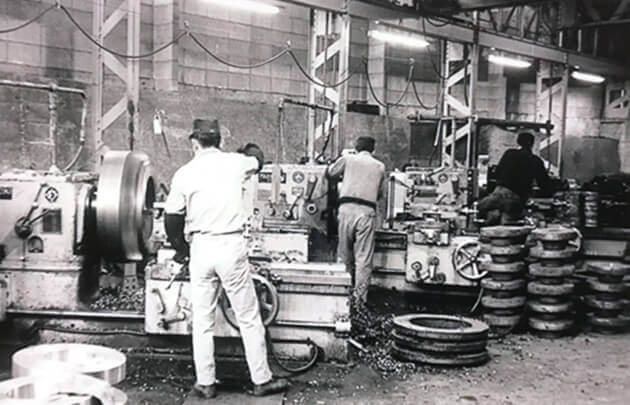

Establishment of integrated production system

Integrated production systems including on-line management system and automated FMS (Flexible Manufacturing System) line were installed.

1990

New company name

Company name in Japanese was changed to Shimoda Flange Co., Ltd. (English name “Shimoda Iron Works Co., Ltd.” was not changed.)

1996

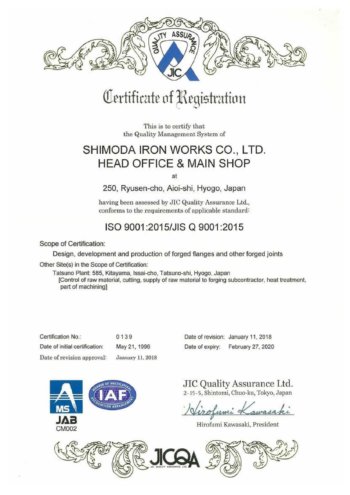

ISO 9001

Acquisition of ISO 9001 Quality Management System.

2007

New machines at North Shop Floor

North Shop Floor was newly constructed at Main Plant. State-of-art machine tools were installed.

2008

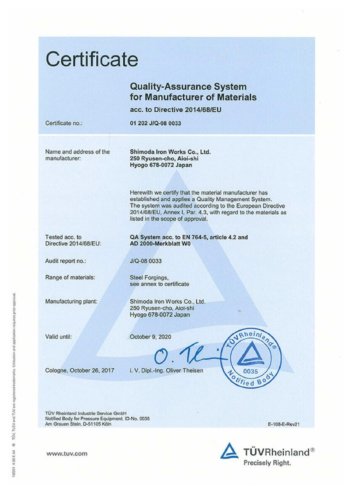

PED 97/23/EC

After acquisition of European Pressure Equipment Directive PED 97/23/EC Annex 1, a variety of forged products were delivered to power and chemical plants in Europe.

2012

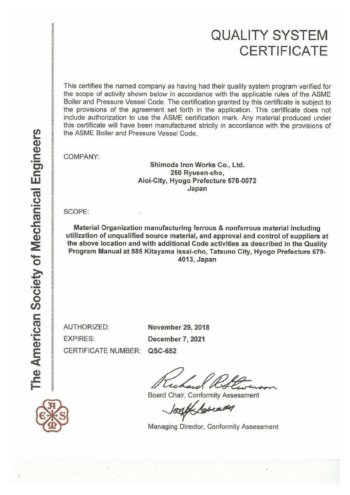

ASME CMO

Acquisition of ASME CMO for nuclear power components.

2013

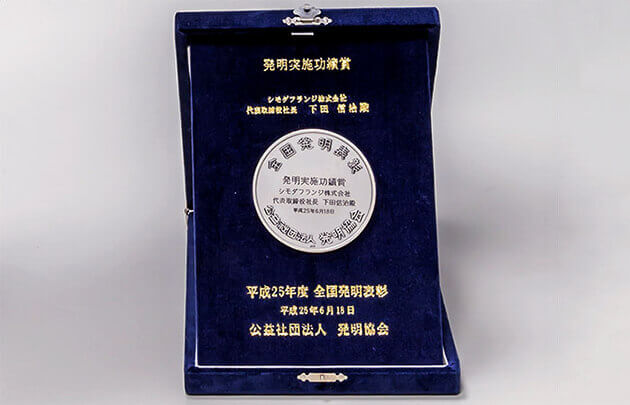

Award of Invention

The Japan Institute of Invention and Innovation awarded Shimoda Flange the “Achievement Award of Practical Application of Invention’‘ for their construction of a forged and fully machined elbow.

2014

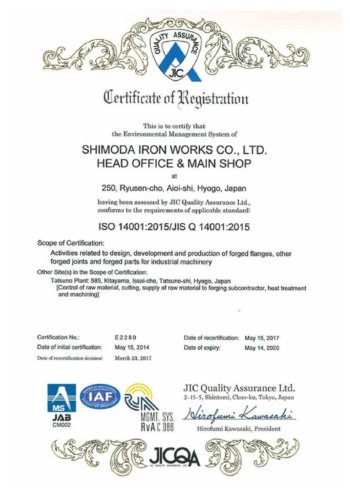

ISO 14001

Acquisition of ISO 14001 Environmental Management System.

2016

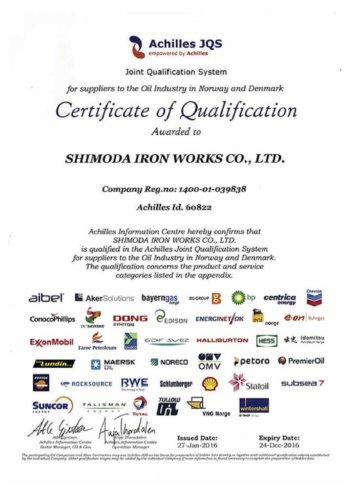

Achilles JQS

Registered by Achilles JQS as a supplier to the oil industries in Norway and Denmark.

2016

Patent of the machining procedure of large screws

Shimoda Flange developed the new machining procedure of large screws having diameter greater than 1,500mm. Applications of such screw couplers to constructions and civil works have been increasing.

2017

New Ryuko Plant

Ryuko Plant is newly constructed at Ryuko, Tatsuno city.

2017

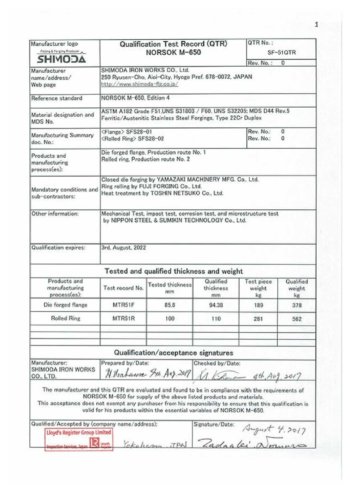

NORSOK

NORSOK is one of the global standard for oil and gas industries. Our forgings made of duplex stainless steel were qualified by NORSOK.

2018

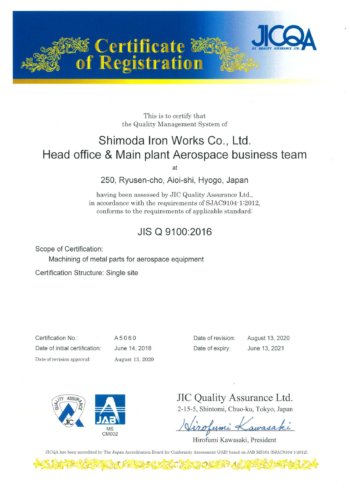

Aerospace certification: JIS Q 9100

Shimoda Flange is certified as a supplier in the scope of machining of metal parts for aerospace equipment.

日本語

日本語